AC-3 dry and wet mix shotcrete machine

From 5000

EUR

In stock

The AC-3 is based on the rotor principle of work. The performance of the AC-3 shotcrete equipment delivers a large margin of safety for operation in harsh conditions, as well as the versatility of dry and wet methods. The machine is recommended to be used for large amounts of laying shotcrete concrete in the conditions of mines, tunneling, and for mounting slopes.

- Impressive vandal-resistant construction with a 10-fold safety margin.

- Easy to move around the construction site.

- Ability to work with both dry and wet methods.

- Height of loading is 1,2 m.

- Ability to work with a filler fraction of up to 20 mm.

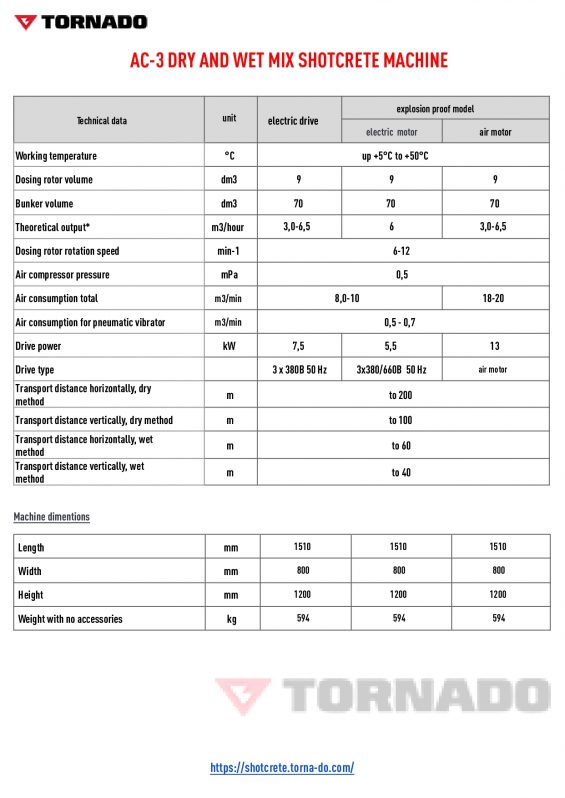

AC-3 dry and wet mix shotcrete machine

AC-3 dry and wet mix shotcrete machine