Repairing reinforced concrete structures: types and restoration options

- Cases

- Theory

- Possibilities

Structures made of reinforced concrete can be very wide-ranging and include bridges, tunnels, cooling towers, port facilities, and industrial buildings. But they all have one thing in common: they all wear out over time, which means that sooner or later they need to be repaired.

Reinforced concrete repair can be done using several methods, but let’s try to analyze which of them is the most functional and allows us to achieve results of the highest quality.

Why is structural repair of reinforced concrete structures necessary?

Reinforced concrete is the most affordable material for creating load-bearing structures. Still, at the same time, it demands constant care and maintenance due to the regular exposure to weathering, ageing, chemical environment, and mechanical and dynamic stress. This is especially true for bridge structures, tunnels, chimneys, and port facilities. Protective coatings of reinforcement as part of shotcrete concrete reinforcement decelerate the degradation of concrete but do not fully protect against external influences and time.

Over time, the reconstruction of buildings and other reinforced concrete structures is inevitable. Shotcrete concrete repair can be done in several ways. Let’s discuss each of them.

Reinforced concrete repair methods

- Repair using repair mixtures

In the context of the common misconception about the potential use of cheap cement-sand mixtures for demanding structural repair, a clarification must be made:

Cheap (without a coarse fraction as well as special granularity and without additives) mixtures are not constructional. Even factory-made cement-sand mixtures are usually used for screeding, masonry, and for plastering.

Concrete structures made in the proper way only get stronger over the years, while even the highest-quality cement-sand mixture will eventually begin to crumble, crack, and fall off.

It is very difficult to do repairs with an ordinary cement-sand mixture due to the two fundamental qualities of concrete:

- The dense structure of the cement grain absorbs almost no water solutions, so the conventional cement-sand mixtures barely adhere to the concrete;

- A thin layer of repair mixture based on liquid concrete causes shrinkage, flaking, and, as a result, repairs with conventional mixture lead to a loss of the applied layer.

That is why special reinforced concrete repair mixtures are used for repair and restoration of damaged concrete. Due to special additives, the concrete repair compound preserves plasticity, strength, and high adhesion to the dusty concrete base.

This method means the application of special repair compositions on the concrete structure in a manual or mechanized way (using plastering machines). Generally, the repair mixtures used are enriched with special additives that give the repair layer the necessary waterproofing, adhesion, and strength properties (the characteristics are provided by the used formula, not by the application technology)

It is worth noting that this type of repair has several drawbacks:

- The most substantial negative factor is an increase in the cost of the work carried out due to the high cost of additives, and high concentration of them. After all, factory repair mixes are quite pricey. For comparison: a simple cement-sand plaster costs 3-4 Euro / 25 kg, shotcrete mixture costs 10-20 Euro / 25 kg and rem-mixes cost 20-50 Euro/25 kg.

- The efficiency of manual application depends directly on the number of workers, and considerable amounts of reinforced concrete repair works involve quite a few dedicated professionals. As a result, in addition to the immediate costs, there are significant additional costs for accommodation, food and transportation of personnel.

To increase productivity, the application of mixtures is sometimes done in a mechanized way using plastering machines. However, not all mixtures can or should be applied by this method (for application of rigid and sticky mixtures, expensive equipment that costs up to 20 000 Euro is required).

- The human factor should not be disregarded either. It is not easy to achieve systematic compliance with the quality requirements of the application of mixtures, and personnel training creates additional costs.

- There is a very large range of repair mixtures available, differing in purpose, layer thickness, and other factors. As a result, when there are different types and scales of damage, it is necessary to use several different mixtures. This complicates the organization of the work and also requires very careful calculation of the amounts of expensive mixtures

- There are also obvious limitations such as the impracticability of manual application or spraying with a shotcrete machine (extensive damage requiring filling the space behind the reinforcement bars, especially on the ceiling surface, for example), for medium and especially large scale of work, the price of mixtures will be extremely high which calls for considering alternative technologies (for example, shotcreting that involves significantly cheaper mixtures)

- Pouring concrete into the installed formwork

This method of repair and reconstruction of buildings and structures is similar to their erection: after preparing the surface, in the place that needs to be repaired, a formwork is installed, and repair voids are filled with concrete mixture. The disadvantages of this method include:

- inaccessibility or obvious impracticality for doing the formwork, pouring and vibrating, inclined and ceiling surfaces, complex configurations and shapes, dense reinforcement junctions, a large number of different damages in a large area, and others;

- achieving improved characteristics of concrete requires the use of expensive additives, which increases the cost (at medium and large volumes it is worth considering the use of alternative technologies, such as shotcreting with relatively cheap mixtures)

complicated access to the workplace (or a situation that requires high-altitude works or erection of multiple scaffolding).

The additional costs must include the price of producing, storing, transporting, and installing the repair formwork. Often such formwork will be unique because of the curvature of the repaired structures.

- Injection

Damaged areas are “glued” from the inside thanks to special adhesive mixtures supplied by specialized injection equipment under high pressure.

The specificity and uniqueness of injection are that this method is used for repairing defects in the form of cracks and internal voids, where it is impossible to perform repairs by methods of applying repair mixtures to the surface.

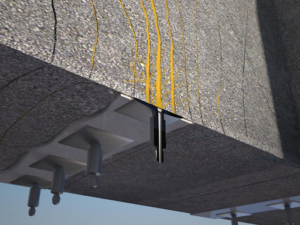

The operating principle of the technology is based on the injection of a repair compound into the body of the building structure under pressure through special nozzles (packers).

Injection, as a rule, cannot be substituted by surface repair methods (manual application, pouring or shotcreting) and vice versa – surface damages cannot be repaired by injection.

- Shotcreting the surface

Shotcreting is the application of concrete mixture to the work surface by compressed air flow. When using shotcreting for repair purposes, the mixture is hammered into the substrate and bonded to it by hitting the surface with the mixture at a speed of up to 200 m/s. The technology does not require the use of formwork. With the impact application and properly selected composition, the concrete is compacted and gains better (by 25% compared to conventional pouring) mechanical properties, such as increased frost resistance, strength and resilience to chemical influences.

Concrete repair with shotcrete: characteristics and advantages

The use of shotcreting, and primarily dry-mix shotcreting, in the repair of concrete, is preferable to other methods because of the increased adhesion (adhesion of the main structure to the new layer) that is achieved with this method. Both layers – the old and the new ones – actually turn into a one-piece monolith with increased strength, which makes it possible to prevent frequent repairs in the future, because the new repair layer, after restoration measures, begins to function together with the main structure.

Characteristics and advantages of shotcreting:

- It allows repairing structures that are subject to dynamic loads such as tunnels, bridges, walls of industrial buildings, port facilities and other objects that are exposed to constant vibration. Repair by plastering with regular vibration of the main structure will not build the necessary adhesion between the layers, and the protective layer will have to be renewed because of the rapid separation.

- High efficiency. Using a shotcreting machine, two professionals are able to apply from 1 to 10 m3 of concrete per hour in comparison with 0.5 m3 of concrete, which one worker can apply by hand during one shift.

- This method can be conveniently used in hard-to-reach places, which is extremely effective in case of irregular destruction. Concrete surfaces are often only partially destroyed, and this creates the need for “spot repair”. The technology of shotcrete spraying, primarily dry-mix, allows applying concrete hundreds of meters away from the place where the equipment is deployed. This is an extremely economical way of saving resources when such a structure needs repair (for example, sewers, drainage structures, chimneys, cooling towers, bridge columns, wharf walls, any other high-rise structures, in the shafts, and so on) where it is difficult to obtain access to the damaged area.

- Saving on shotcrete mix. When shotcreting, the adhesion to the surface, strength, frost resistance, water resistance and other characteristics of the mixture are achieved through mechanical compaction and properly selected composition of aggregates, rather than the chemical composition of additives in the shotcrete mixture. This feature helps to reduce the number of additives used in the shotcrete mix or even completely refuse from using them and, as a consequence, significantly reduce the cost of the shotcrete mix.

- Reduced impact of the human factor on the final result of the work. The concrete mixture is hammered into the substrate layer by layer thanks to the impact force, which in itself ensures high quality of repair layers. The mixture that is not perfectly poured or excessively wetted bounces off the surface when shotcreting. Yes, the bounce is a kind of payment for the high quality of the mixture, yet it also provides the desired strength to the repair layer.

How to choose the suitable type of structural repair?

Structural repair is an inevitable part of the life cycle of any reinforced concrete structure, and each of the methods described above may be suitable for you under certain conditions. But there are situations when shotcreting is the only possible method from a functional and qualitative point of view, and it can also help to avoid paying unnecessary costs. Based on Tornado’s extensive experience in concrete repair, our trained professionals will be happy to look into your case and help you decide on the repair method that’s most suitable for your case. You can also rely on our support in taking further steps such as selecting the most efficient equipment and high-quality mixes.

- Theory

- Possibilities

Stages and shotcreting cost in the repair of reinforced concrete structures by shotcreting

- Cases

- Theory

- Possibilities

Repairing reinforced concrete structures: types and restoration options

- Theory

- FAQ

Dry-mix and wet-mix shotcreting: comparison and applications

- Theory

Dictionary of shotcrete terms

- Economics

- Theory