AC-2 dry and wet mix shotcrete machine

From 5000 EUR In stock

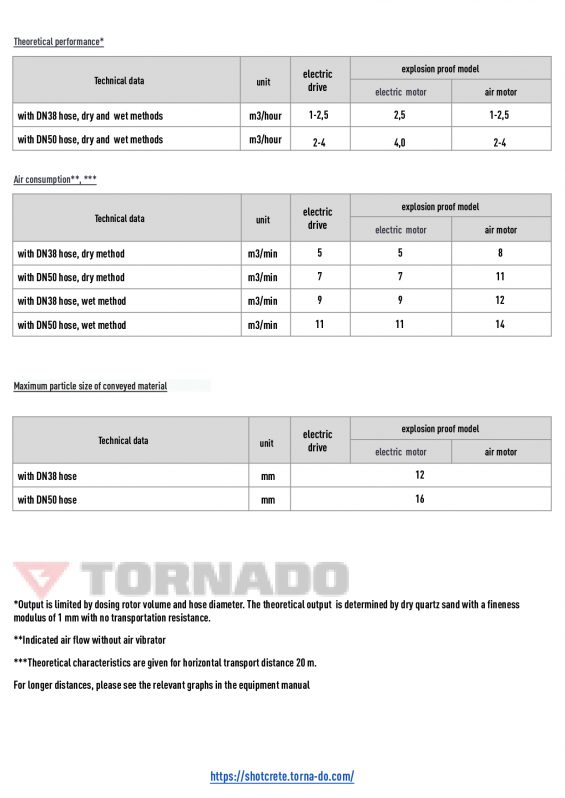

The AC-2 is based on the classic rotary principle with the drum revolver type.

The performance of the machine provides a large margin of safety, high reliability of accessories, and the probability of working with shotcrete materials (gunning materials) of any density, including refractory mixtures with a large angle of slope. Flexibility in use allows adapting the AC-2 to most types of shotcrete work.

- Classic design with two sealing plates.

- The most compact of revolver machines.

- Reliable disk variator for smooth performance changes.

- Conveniently works with fine-grained and powdery mixtures.

- An extra mixer provides full mix coverage.

- Dosing drum cells, even with wet mixes.

- Height of loading is 1,1 m.

AC-2 dry and wet mix shotcrete machine

AC-2 dry and wet mix shotcrete machine